Deep|AMAT: Structural Capital Intensity Shift to Materials Engineering

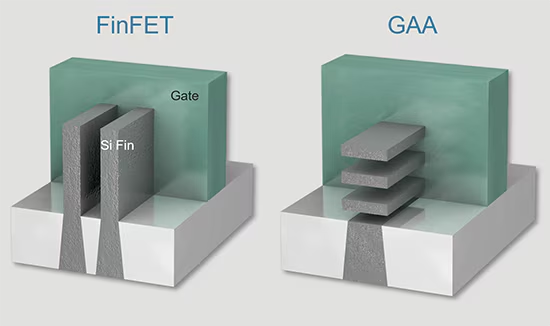

Our positive stance on Applied Materials (AMAT) is predicated on a fundamental divergence in semiconductor manufacturing physics. For the past decade, lithography has been the primary driver of wafer cost. However, as the industry transitions to 2nm Gate-All-Around (GAA) and Backside Power Delivery Networks (BSPDN), the primary scaling bottleneck shifts from “printing smaller lines” to “building complex 3D structures” and “engineering new materials.”

This architectural shift triggers a structural increase in capital intensity for Deposition (PVD/CVD/ALD) and Removal (CMP/Etch). Applied Materials, with its breadth of portfolio and dominance in integrated vacuum platforms, is the primary beneficiary of this transition.

Our latest supply chain investigation indicates an accelerating revenue trajectory from TSMC. AMAT’s revenue contribution from TSMC to grow 20-30% YoY in 2026 , with momentum expected to accelerate even further in 2027. This ramp is underpinned by the simultaneous high-volume manufacturing adoption of GAA and the subsequent deployment of BSPDN, which disproportionately benefits AMAT’s specific product portfolio compared to prior FinFET generations.

The 2026 Inflection: TSMC N2 Ramp

The growth in 2026 corresponds to the volume ramp of TSMC’s N2 node. Unlike the transition from N5 to N3, which was a FinFET shrink, N2 introduces GAA transistor. This architecture requires the deposition of alternating Si/SiGe layers and significantly more complex Gate Metal stacks. This drives immediate demand for AMAT’s Epi and CMP tools, as planarization steps increase by an estimated 20-30% to manage the topography of the new gate structure.

Figure 1: Comparison between FinFET and GAA

Source: Applied Materials

Note: The visual highlights the multiple layers of the gate stack wrapping around the channels, illustrating the increased complexity in deposition and removal steps required for the 2nm node.

The 2027 Acceleration: TSMC A16 & BSPDN

We anticipate the growth rate in 2027 to surpass 2026 levels, driven by the superposition of Backside Power Delivery (Super Power Rail) on top of the GAA architecture. BSPDN is an additive process module. It does not replace front-end lithography steps but adds a massive backend module involving wafer reversal, bonding, extreme thinning, and thick metal deposition. This opens a net-new TAM for AMAT in Backside PVD and Silicon CMP, which were virtually non-existent in the N3 node.

Technical Deep Dive: Logic - GAA & BSPDN

To understand the durability of this thesis, we have to understand the physics constraints at the Angstrom level.